The inverted emission microscope is a backside analysis system designed to identify failure locations by detecting the light and heat emitted from the defects in semiconductor devices.

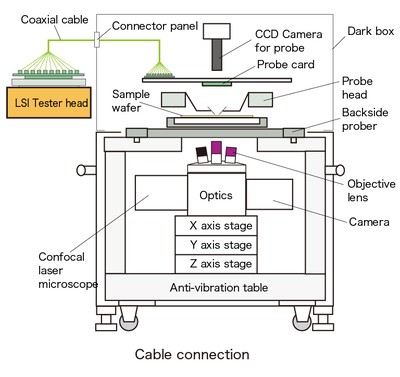

The signal detection from backside facilitates the use of probing and probe card to the wafer surface, and the sample setting can be performed smoothly. The platform, possible to mount multiple detectors and lasers, enables the selection of the optimum detector for performing various analysis methods such as light emission and heat generation analysis, IR-OBIRCH analysis, and others; moreover, letting dynamic analysis perform efficiently by tester connection.

●iPHEMOS-MP

Support for measurement from a single chip to a wafer by mounting a 300 mm wafer prober. Multi-pin needle contact by probe card and sample observation on PC board are available. Dynamic analysis with LSI tester drive is also possible by cable connection.

The iPHEMOS-MP superimposes the emission image on a high-resolution pattern image to localize defect points quickly. The contrast enhancement function makes an image clearer and more detailed.

Display function

| Line voltage | AC 200 V (50 Hz/60 Hz) |

|---|---|

| Power consumption | Approx. 1400 VA (Max. 3300 VA) |

| Vacuum | Approx. 80 kPa or more |

| Compressed air | 0.5 MPa to 0.7 MPa |

| Dimensions/Weights | Main unit: 1740 mm (W)×1150 mm (D)×1770 mm (H), Approx. 1400 kg Control rack: 880 mm (W)×700 mm (D)×1542 mm (H), Approx. 255 kg Optional desk: 1000 mm (W)×800 mm (D)×700 mm (H), Approx. 60 kg |

*Weight of iPHEMOS-MP main unit includes a prober or equivalent item.

日本滨松光子学株式会社(HAMAMATSU)是全球光子技术、EFA领域的领导企业。自1953年成立以来,EFA失效分析产品销往全球半导体各大企业,拥有数量最多的半导体和面板行业客户。HAMAMATSU为客户提供EFA失效分析领域的缺陷定位解决方案,开发的微光显微镜是业界主流的高分辨率热点定位设备,且拥有多项专利产品。设备具备Thermal,EMMI,OBIRCH等分析功能方法。